Straw can be used for bedding, fodder, and for the production of bioheat. The use of straw as bioenergy has been increasing in the last ten years. Many farmers have invested in straw heating systems to heat livestock rooms and residential buildings on the farm. There are many who grow grain in combination with chicken and/or pig production. These productions, and especially chicken production, have a large heating requirement, and many have solved this by investing in straw heating systems.

Climate benefit

Straw is a renewable resource and CO2 since it has a short cycle time from breakdown in the soil and incorporation into a new plant during next year's photosynthesis. Working it into the soil can help to increase or at least maintain the carbon content in the field soil and it is not recommended to remove the straw every year.

It has been common to set the climate effect to zero when we fire with biofuel. It can still be debated whether this is so. Some (fossil) fuel is used for packaging and transport and this is calculated for 7 g of CO2 per kWh. A straw boiler will also be produced and this has a climate footprint. Another way to calculate the climate benefit is to look at which heat source is replaced. If it is propane with emissions of 230 g CO2 per kWh, replacing it with bioenergy provides good climate benefits, regardless of how we calculate.

Energy

The energy potential for using straw for bioenergy is estimated at around 4.5 TWh. 1 TWh corresponds to 1 billion kilowatt hours, which corresponds to the energy needs of 50,000 residential buildings.

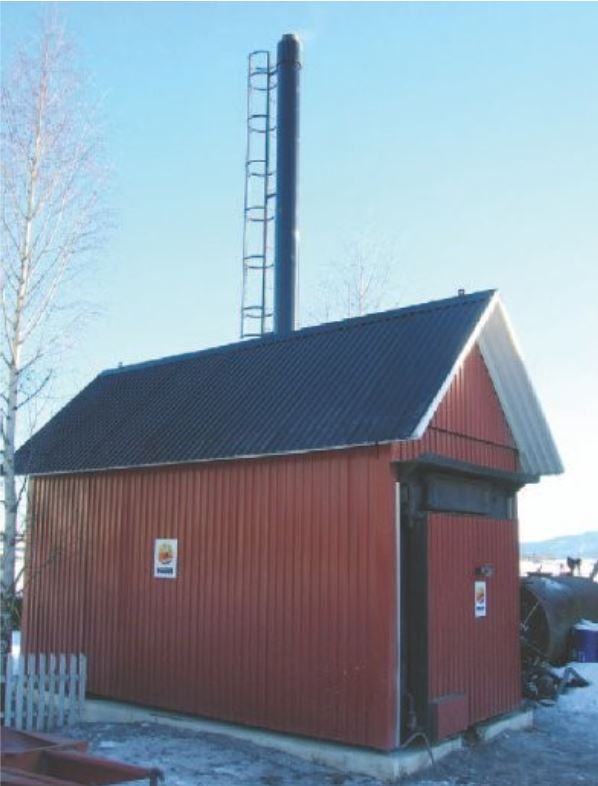

Straw to be used in heating systems must be dry when harvested and stored dry. At 15% moisture, the calorific value is 4 kWh/kg straw. Damp straw gives a lower calorific value and stronger smoke generation from the straw plant. Smoke from straw plants can be a problem for the environment. The strongest smoke development will be just after placing new straw bales, before the firing is well under way.

The amount of straw varies according to which types of grain are grown, and the height of the stubble when the grain is harvested. The use of straw shortening agents will also reduce the quantity. Harvestable amount of straw will be between 60 -70 % of the grain crop.

A high content of potassium in straw leads to some deposit of slag in the boiler room. This must be removed over time to maintain good heat capacity.

If the straw is removed from the soil every year and used as fuel, it can eventually lead to a certain decrease in the content of organic material in the soil. Organic material is important for maintaining soil life and favorable soil structure. It is therefore recommended to plow down the straw every 3 years.

Task:

A farmer has a grain area of 250 acres, and has achieved an average yield of 475 kg of grain per acre. All the straw must be used in the straw plant built on the farm.

a) How dry should the straw be before it is put in storage?

b) How much energy can you expect to get if all the straw is burned in the straw plant?

More information on the topic

Video from Hauer Gård and horticulture https://youtu.be/xqmhk99RlpU